Area-saving system of shield departure

This environmentally friendly system reduces both departure lots and construction sludge

Characteristics

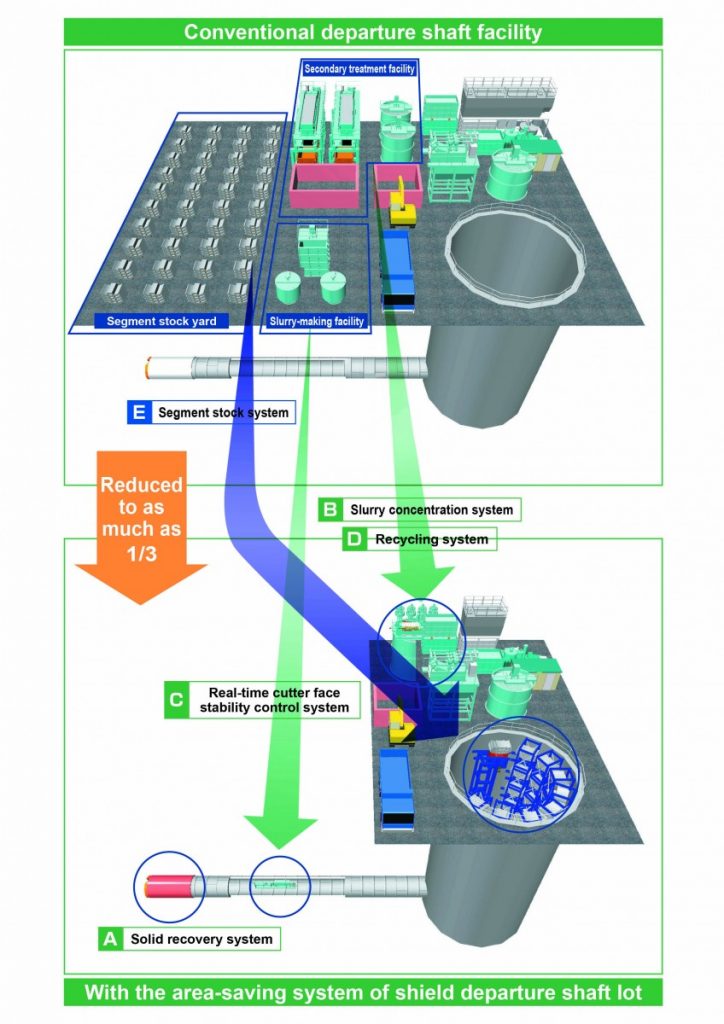

The area-saving system of shield departure reduces shield departure lots with the following technological elements:

- Reduces secondary treatment soil.

It cuts clayey soil mounds to the maximum size that can be transported via sludge removal pipes and recovers it in a solid form. - Reduces the lot for secondary treatment facilities.

In place of the conventional filter-press, this system concentrates surplus slurry without adding agents. - No need to make sludge on ground.

By using a special polymer-based agent, the system aims to stabilize the cutter face of clayey soil. - Reduces segment stock yards.

It three-dimensionally installs a device to stock segments in a shaft or a lot to automate the transportation to under the shaft. - Reduces construction sludge.

The solid recovery system not only increases the primary treatment soil but also makes it possible to recycle concentrated slurry as fluidization treated soil.

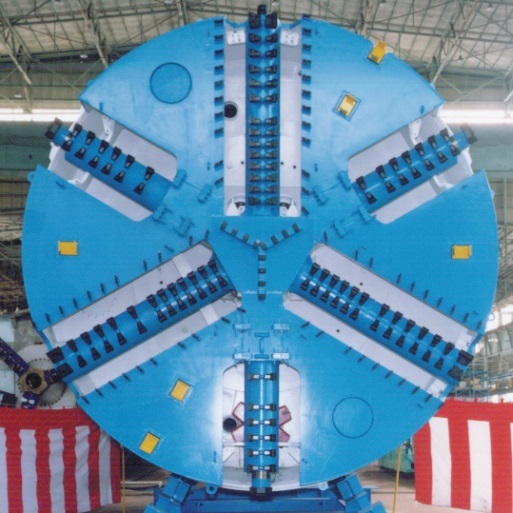

Mechanism of tunnel driving

The area-saving system of shield departure does not simply stratify facilities but rather reduces the shield departure lot to 1/2 to 1/3 of conventional systems (in case of slurry shield) by combining technological elements, such as reducing the facility size itself. It also reduces construction sludge by collecting soil from clayey soil mounds in a solid form and increasing the primary treatment soil. Since no agent is added to the concentrated slurry, it can also be reused as fluidization treated soil.

Applications to actual tunneling

- Reconstruction work near Sotokanda

Chiyoda Ward

Tunneling diameter: φ3.07m

Tunneling length: 375m

Departure lot area: 600㎡ - Taito Main Line construction

Tunneling diameter: φ5.85m

Tunneling length: 1,007m

Departure lot area: 600㎡ - Shin-Akasaka Main Line construction

Tunneling diameter: φ3.29m

Tunneling length: 733m

Departure lot area: 780㎡