Excavantion mechanism

- Flexible cross section

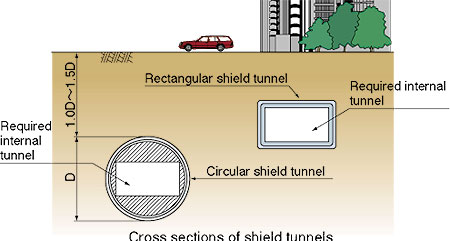

Shield tunnels of various cross sections can be constructed.

- Compact shield tunneling machine

Rectangular shield tunnels can be constructed using a simple excavation mechanism.

The weight and length of the shield tunneling machine, and the cost of excavation can be reduced by using hydraulic jacks. - Structure of lining of rectangular shield tunnel

The lining of the rectangular shield tunnel has an effective sandwiched structure. The outside of the tunnel has a steel-concrete composite structure composed of steel shells that are used as main tension members. The inside has a reinforced concrete structure.

Using steel shells not only for temporary linings during temporary work but also for the main tunnel upon completion of tunnel linings leads to the reduction of construction cost.

Characteristics

- Cutter wagging system

Cutters are expanded and contracted like pistons by hydraulic jacks. Thus, the structure is mechanically simple and the weight and length of the tunneling machine can be reduced.

- Overcutters

The rotation of cutters and the expansion and contraction of overcutters are automatically controlled to enable accurate excavation of corners of the cutting face.

- Spike bits

Long stroke cutters essential to the non-circular wagging cutter shield method are required to have higher durability and reliability than ordinary cutters.

The newly developed high-performance "spike" bit is capable of penetrating and cutting the earth when the overcutter is expanded or contracted, and before and after the cutterhead is wagged.

Applications to actual tunneling

-

Data on the construction

of the Magome trunk sewer

Cross section:

5.24 m diameter

Method:

Earth pressure balance

shield method

Construction length:

1,309 m

Maximum overburden depth:

44.0 m

- Data on the construction of the Tozai Line of Kyoto Rapid Transit (Rokujizo construction section) Cross section: 9.9 m wide and 6.5 m deep Method: Earth pressure balance shield method Construction length: 120 m Maximum overburden depth: 7.0 m

-

Data on the construction of Kiramekidori

Street, an underground walkway

Cross section: 7.81 m wide and 4.98 m deep Method: Earth pressure balance shield method