Characteristics

- Increased fluidity of excavated soil

In gravel layer, rheological foams work as ball bearings and increase the fluidity of excavated soil. - Reduction of fluctuations in face pressure

The compressive character of rheological foams can reduce fluctuations in face pressure. - Higher watertightness of excavated soil

The groundwater in void space between soil particles of excavated soil is replaced by tiny foams, so the excavated soil can have higher watertightness. - Effectiveness in preventing adhesion of excavated soil

In the case of hard cohesive ground, adhesion of excavated soil on the shield face plate and inside the chamber is prevented. - Easy treatment and disposal of excavated soil

Excavated soil is restored to the original state when it was in the ground and therefore, transportation and disposal of excavated soil is handled easily. - Improvement of working environment

As clay or bentonite is not used, the tunnel remains clean and the working environment is improved. - Downsizing of equipment

Only small equipment is required for creating and injecting foams.

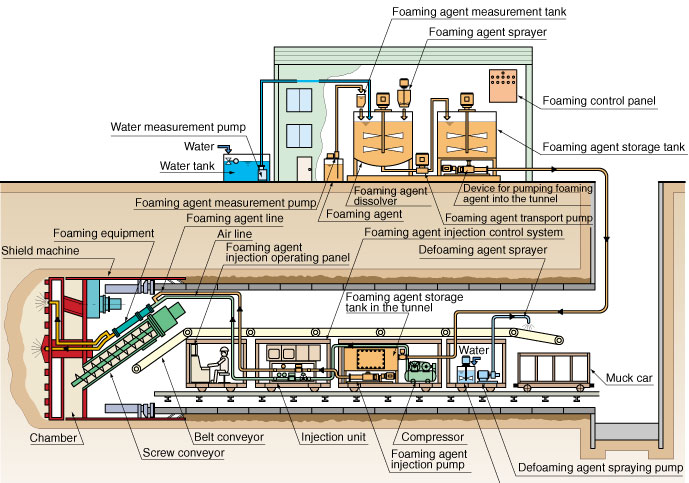

Principle of Rheological Foam Shield Tunneling Method

Mechanism of tunnel driving

Using the Rheological Foam Shield Tunneling Method, the tunnel is excavated while injecting foam into the face and the chamber. Foams are generated with a special foaming agent. Injected tiny foams with properties similar to those of shaving cream can improve the fluidity and the watertightness of excavated soil. Foams can also prevent the soil from sticking inside of the chamber. This enables smooth tunnel driving while keeping face stability. In addition, removed soil with foams can be defoamed and put back the state before foam injection. Therefore, transportation and disposal of excavated soil is handled easily, making it a highly economical method.

Applications to actual tunneling

-

【Large-section shield tunneling】

Construction of underground section of Hanshin Electric Highway line near Fukushima

(Diameter: 10.8m, Length: 210m)

-

【Long-distance, small-radius-curve shield tunneling】

Improvement of the Higashi-Kibogaoka storm sewer in the Midori treatment district

(Diameter: 6.15m, Length: 2,050m, Curve radius: 20m)