Characteristics

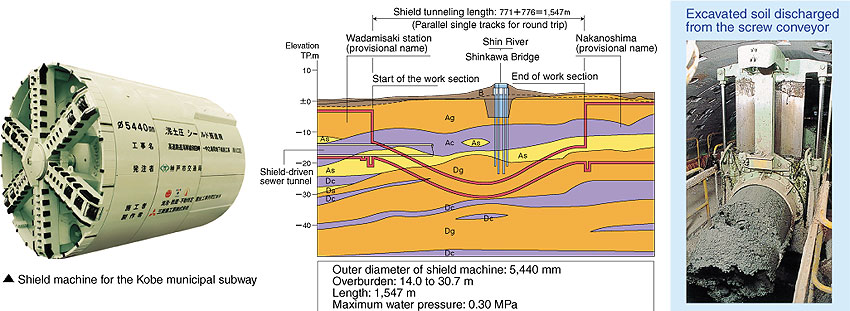

- Excavation in high-water-pressure gravel layer at great depths using muddy soil pressure

Safe excavation is ensured by controlling high water pressure and preventing blows or face collapse. - Adaptability to the soil or groundwater condition

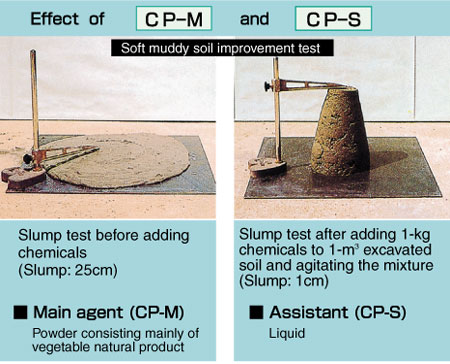

Adjusting the volume of chemical additives or changing to an ordinary muddy soil shield method is easy. - Improvement of excavated soil

Excavated soil can be improved to make a soil without fluidity, which can be transported out of the tunnel as an ordinary excavated soil. - Use of environmental-friendly safe material

Main chemical agent and assistant are safe to both humans and animals, and neutralize the improved soil.

Mechanism of tunnel driving

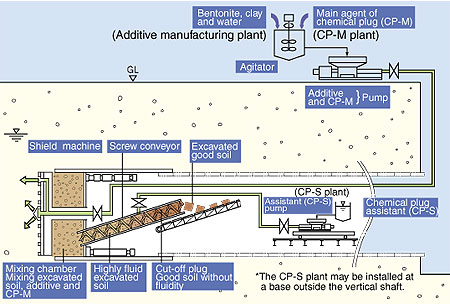

An additive and the main chemical agent are mixed with the excavated soil in the chamber. Then, the assistant is injected into the screw conveyor to create a cut-off plug from improved soil. This enables safe and accurate excavation in water-bearing gravelly soil under high water pressure while controlling face pressure and preventing face collapse due to blow and other soil disturbances.

Tunneling system and effect of chemicals

Equipment for mixing the main agent of chemical plug (CP-M) is installed at the additive manufacturing plant, and that for injecting the assistant (CP-S) is installed in the screw conveyor.

The excavated soil mixed with CP-M is mixed with CP-S and agitated in the screw conveyor, and rapidly changed into improved soil to form a cut-off plug that resists high water pressure.

Applications to actual tunneling