Characteristics

- Applicability to a wide range of soil types

This method is applicable to diverse soil types because sand, gravel, silty clay, Shirasu, and alternations thereof can be converted to muddy soil with plastic fluidity and impermeability using mud making agent. - Minimization of settlement

The face is retained by muddy soil and thus there occurs hardly any disturbance of the soil. Ground surface settlement can therefore be minimized. - Simultaneous backfilling

Shield perimeter and the kneading chamber are waterproofed by muddy soil, so no backfill material affects the face. Simultaneous backfilling is thus ensured. - Applicability at great depths and under high water pressure

Tunnel driving tests under a maximum water pressure of 0.7 MPa have confirmed satisfactory performance of the method under high water pressure. The method is applicable to great depths exceeding 50 m.

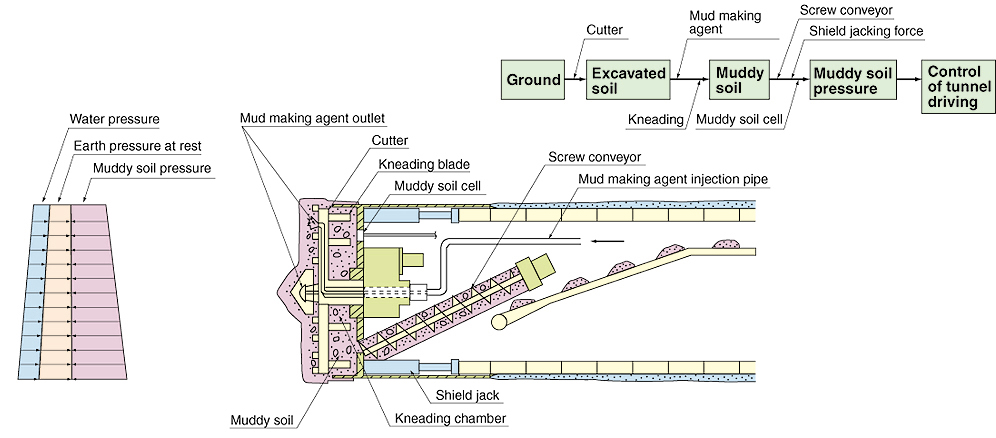

Principle of DK shield method

The DK Shield Method controls muddy soil pressure in three phases to minimize disturbance to the ground, and thus controls tunnel driving.

- Convert excavated soil into muddy soil

Mud making agent is injected into soil that has been excavated from the tunnel by a cutter. Excavated soil is then kneaded forcefully with the agent using kneading blades and changed to muddy soil with plastic fluidity and impermeability. - Stabilize the face with muddy soil

Kneading chamber and screw conveyor are filled with muddy soil. Then, muddy soil pressure is generated by the thrust of a jack to resist groundwater pressure and earth pressure for providing face stability. - Control tunnel driving by muddy soil pressure

Muddy soil pressure is constantly monitored using muddy soil cells attached to the bulkhead. Tunnel driving is controlled by changes in the rate of shield advance and the rotational speed of the screw conveyor so that muddy soil pressure becomes equivalent to the total of earth pressure at rest and water pressure.

Mechanism of tunnel driving

Applications to actual tunneling

-

Construction on the Keihin-ushioda power

transmission line by Tokyo Electric Power Company

(Diameter: 5.03 m)

-

Second-phase construction of the Ohta main

sewerage tunnel by the Tokyo metropolitan

government (Diameter: 8.21 m)

-

Metropolitan expressway, Central Loop

Shinjuku Line (outer line) by the Metropolitan

Eexpressway Public Corporation

(Diameter :12.02 m)