Characteristics

- Construction of high-quality linings

Denser concrete with greater strength enables the construction of high-quality concrete linings.

- Linings with a broad range of applications

This method enables rational construction of concrete linings according to the site condition such as reinforced concrete, nonreinforced concrete, fiber-reinforced concrete, steel-reinforced concrete and prestressed concrete linings. - Superiority of working conditions in tunnel

This method can be applied to mountainous tunneling, and as working conditions in the tunnel is superior compared to the conventional tunneling method, cost for ventilation facilities can be minimized. - Minimization of ground settlement

- Saving of construction time and cost

The type of lining can be selected according to the geological condition, and secondary lining can be eliminated depending on the use of the tunnel. Construction cost therefore can be reduced and construction period can be shortened.

Mechanism of tunnel driving

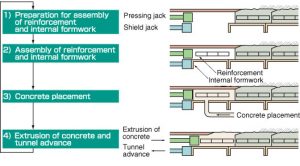

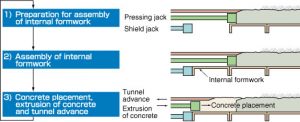

Construction flows by lining reinforcement method

- When reinforced concrete is used

(cyclic concrete placement)

- When nonreinforced concrete is used

(continuous concrete placement)

Applications to actual tunneling

Construction of the second Shinano-gawa water tunnel

Diameter : 8.40 m

Construction length: 3,100 m

Major soil type:Sandstone and

siltstone

Use:Waterway

Depth of tunnel:2.0m to 80.0m

Konan shield tunneling

Diameter: 6.60 m

Construction length: 1,860 m

Major soil type:Diluvial gravel

layer

Use:Utility conduit

Depth of tunnel:11.4m to 17.0m

Construction of the east side of the Akima Tunnel on the Hokuriku Shinkansen railway line

Cross section: 10.70 m wide

and 9.92 m high

Construction length: 3,805 m

Major soil type:Tuff

Use:Railway

Depth of tunnel:Maximum 220.0m

Main civil engineering work as part of the construction of new Hidaka power plant

Diameter: 3.99 m

Construction length: 6,082 m

Major soil type:Lava and

mudstone

Use:Floodway

Depth of tunnel:Maximum 190.0m