Characteristics

- Free choice of docking point

Docking point can be selected freely without any restrictions of surface traffic, underground utilities or submarine conditions. > - Safe and reliable

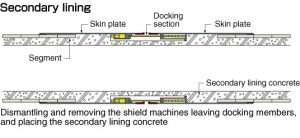

Docking and dismantling of shield machines has been done in narrow space where the ground was exposed. The Mechanical Shield Docking (MSD) Method enables steel rings to directly bear earth and water pressures, and ensures safe and reliable work without exposing the ground. - No adverse effects on the surrounding environment

The MSD Method causes neither ground settlement nor uplift and involves no surface work, so it has no effects on surface traffic or the neighboring environment. - Shortening of construction period

The MSD Method requires no auxiliary measures and enables easy mechanical shield docking, so it achieves a reduction of construction time, compared to conventional methods. - Cost reduction

Costs can be reduced because no auxiliary measures for stabilizing the ground and shaft are required.

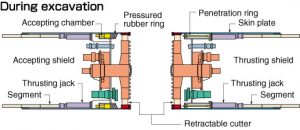

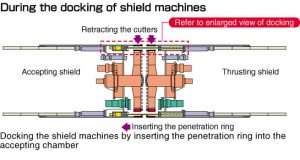

Mechanism of tunnel driving

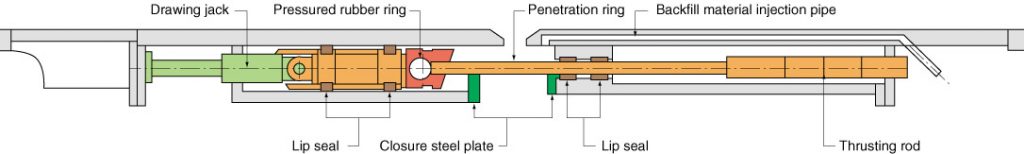

Enlarged view of docking

Applications to actual tunneling

Construction of gas pipeline at the new Nagoya thermal power plant

Diameter: 4.10 m

Length: 1515 m (707 m + 808 m)

Shield type: Slurry shield

Soil at the docking point: Clay and sand

- Thrusting shield machine

- Accepting shield machine